Close

Comfort

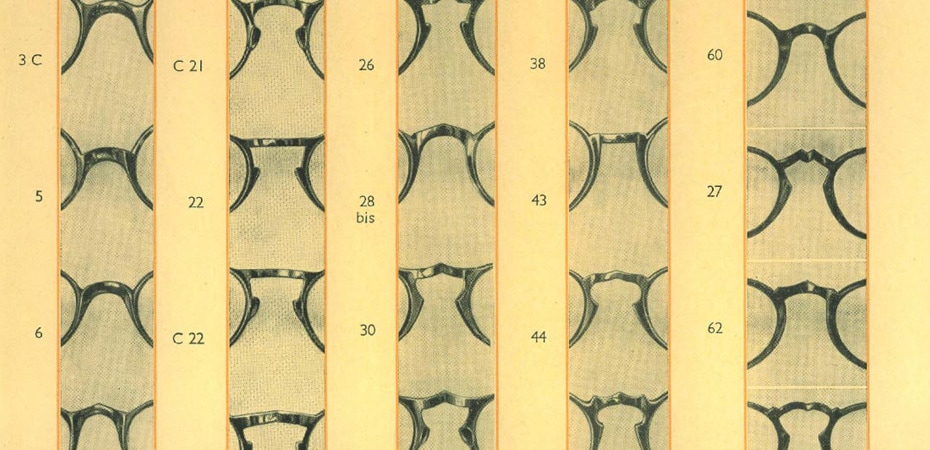

In the early history of Persol, when the glasses were

produced in small volumes, the company also offered more than four

different sizes for each pair of glasses, bridges of various heights and

widths and arms of various lengths – all in the name of making each

pair of glasses essentially “made to measure” so they would be as

comfortable as possible.

In the early history of Persol, when the

glasses were produced in small volumes, the company also offered more

than four different sizes for each pair of glasses, bridges of various

heights and widths and arms of various lengths – all in the name of

making each pair of glasses essentially “made to measure” so they

would be as comfortable as possible.

Particular care is still devoted to evenly

distribute the weight of the glasses across their entire surface through

a special process called “telatura” that consists of eliminating

edges on the underside of the bridge to make the fit more comfortable.

This manual process was first introduced when Persol founder Giuseppi

Ratti still ran the company and is still applied with the same precision

and attention today.

Research into

comfort also led Persol to create a foldable acetate frame in the 1960s,

perhaps the first of its kind.